FIN COOL®

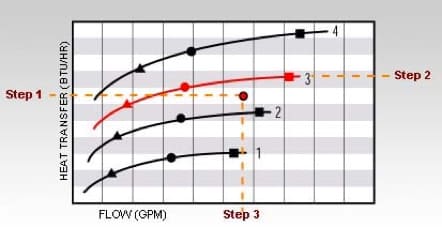

Selection Procedure

Step 1

System flow rate (GPM) of hot liquid

Step 2

Heat transfer requirement = input energy lost to heat 1 HP = 2545 BTU/HR

Performance curves based on Inlet Temperature Difference (ITD) of 50°F ITD = (Inlet temperature of hot liquid) - (Ambient temperature of air)

If ITD is not 50°F: Heat transfer requirement = Input energy lost to heat x 50°F/ITD

Step 3

Select curve for heat exchanger model at or above heat transfer requirement

500 FPM |

1000 FPM |

1500 FPM |

2000 FPM |

|

|---|---|---|---|---|

| Air Velocity Multiplier 1 ROW - Style A | 1.2 | 1 | 0.9 | 0.8 |

| Air Velocity 2 ROW - Style B/C | 1.3 | 1 | 0.9 | 0.8 |

Plotted pressure drop (PSID) values based on viscosity of 50 SSU. If viscosity is not 50 SSU, multiply PSID value by tabulated multiplier to obtain estimate of actual PSID:

Viscosity |

PSID Multiplier |

|---|---|

| 50 SSU | 1 |

| 100 SSU | 1.75 |

| 150 SSU | 2.3 |

| 200 SSU | 2.75 |

| 250 SSU | 3.2 |

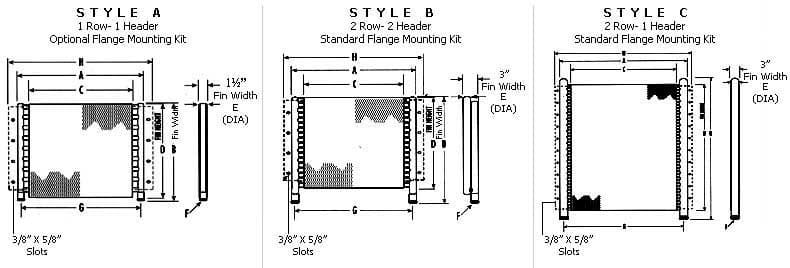

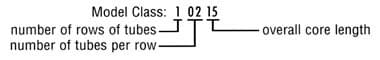

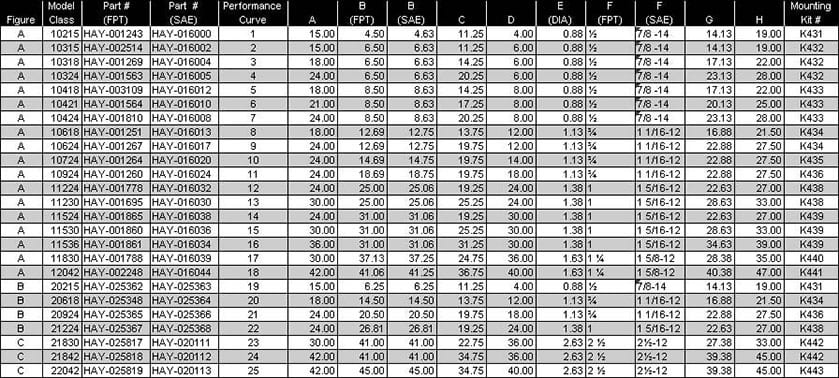

Dimensional Data

Figure letter refers to the diagrams above. Dimensions are in inches. Performance Curve # refers to the Performance Charts below.

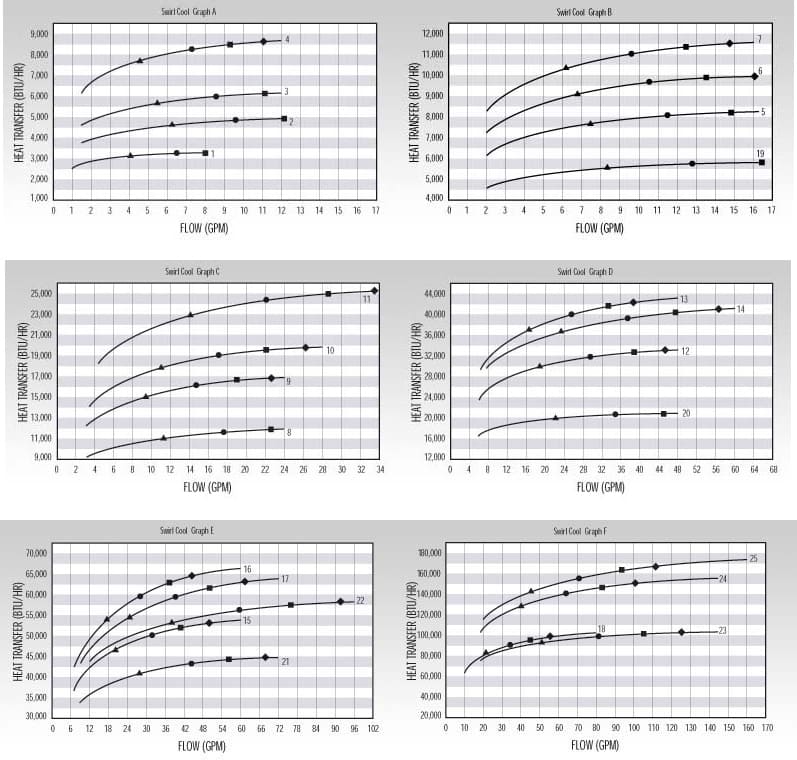

Performance Charts

Heat transfer performance based upon 50°F ITD with barrel style motor. See Selection Procedure for sizing heat exchanger.